- Home

- Company

- Corporate Governance

- Statutory documents

- Financial statements

- Analytical information

- Society development strategies

- Essential facts

- General Meeting of Shareholders

- Tenders and auctions

- Acquisition of shares by a company

- Information about dividends

- Affiliates

- Supervisory Board and Audit Commission

- Internal documents

- Archive

- Archive-Financial statements

- Archive-General Meeting of Shareholders

- Archive-Essential Facts

- Archive-Short-term strategies for the development of society

- Archive-Information about competitions (tenders) and auctions

- Archive-Information on the acquisition of shares by the company

- Archive-Information about dividends

- Projects

- PDMS

- Contacts

100015, Republic of Uzbekistan, Tashkent, Mirabad district, st. Shakhrisabzskaya 22

In early 2008. the management of Teploelektroproekt JSC decided to introduce a software product "AVEVA Plant" at the institute and concluded an agreement with the company "AVEVA" for the purchase of 8 licenses and training by the staff of the institute. In a short time, all the necessary equipment and materials were prepared and purchased, separately a specialized room for training was allocated and a group of specialists from various departments of the institute. The implementation of the AVEVA Plant software product took place in several stages. At the first stage it was eight workplaces were installed to train specialists in the basics of working in the AVEVA Plant system to create 3D model and obtaining documentation, as well as system administration and creation of a catalog of elements. The AVEVA Plant (PDMS) software product is a set of integrated applications for various directions (technology, construction, electrical part, etc.), allowing detailed design and create a three-dimensional model of the future power plant, including any technological installation and equipment. In the center of the unique AVEVA technology, the elements of the future enterprise are presented in the form of objects - for example, pipelines, pumps, etc. Each object is equipped with several levels of information: schematic information in 2D, 3D model data, manufacturing documentation, relationships between project data. It should be especially noted that the developers of AVEVA Plant (www.aveva.ru) periodically update their software product, which greatly simplifies the work in the system and its compliance with changing conditions. final the result of designing in the AVEVA Plant system is the creation of a color three-dimensional model and how derivative, obtaining high-quality project documentation that meets all standards.

The main and important "plus" of this program are

A set of functions for enterprise lifecycle management (workflows, changes, customization, document management), which allows you to integrate and effectively manage all workflows and information networks.

Integrated schematic and 3D model.

Flexibility in choosing design tools in P&ID and other applications.

The world's most productive 3D plant design solution.

Implementation of geographically distributed projects.

A data-neutral storage solution according to the ISO 15926 standard that allows you to store concatenated structured data (schema, 3D, XML, and documents) independent of the applications in which it was developed.

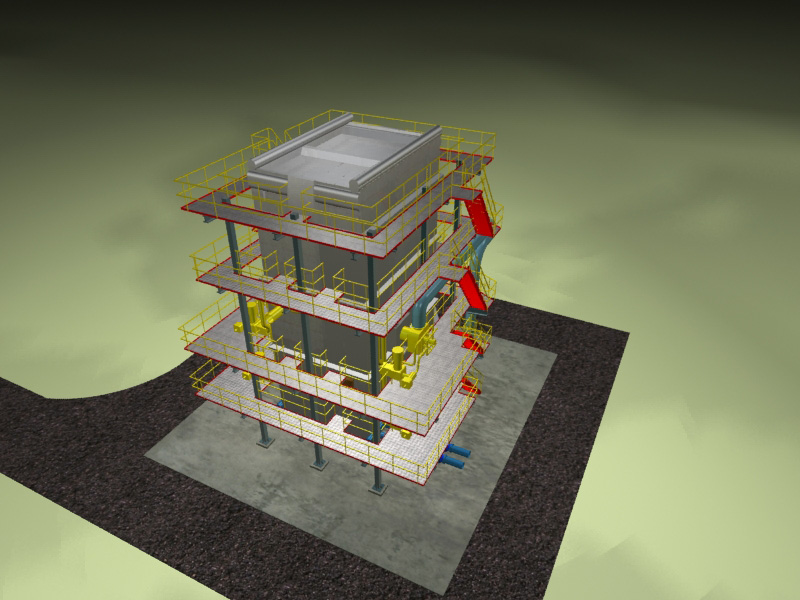

Then the stage of “debugging” the program was started, and the learning process was continued with the involvement of specialists from the leading design and survey institute in the field of energy from neighboring countries with more than 10 years of experience in the program. The result was the implementation of a pilot project of an oil chamber model fully modeled in the AVEVA Plant system.

Models and project data created in the process of working with AVEVA Plant are stored in a single integrated database. Thus, the system forms a consistent picture of the project implementation, and this experience can be used in the design of other objects. All documentation, according to which the construction of the facility will be carried out, is formed on the basis of the data obtained during the modeling. At the same time, two-dimensional drawings, reports, specifications are automatically changes are made if the model has been changed.

Kurgan thermal power plant

Kurgan thermal power plant

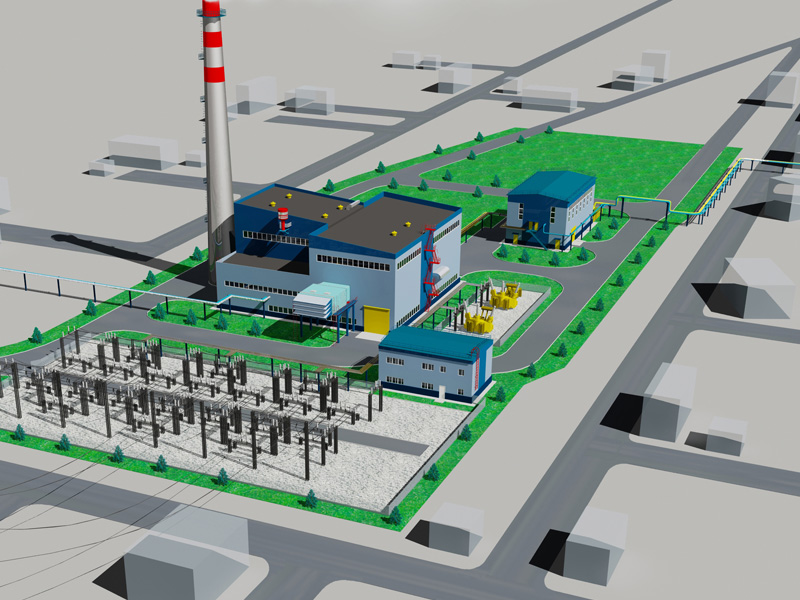

Tashkent CHP

Tashkent CHP

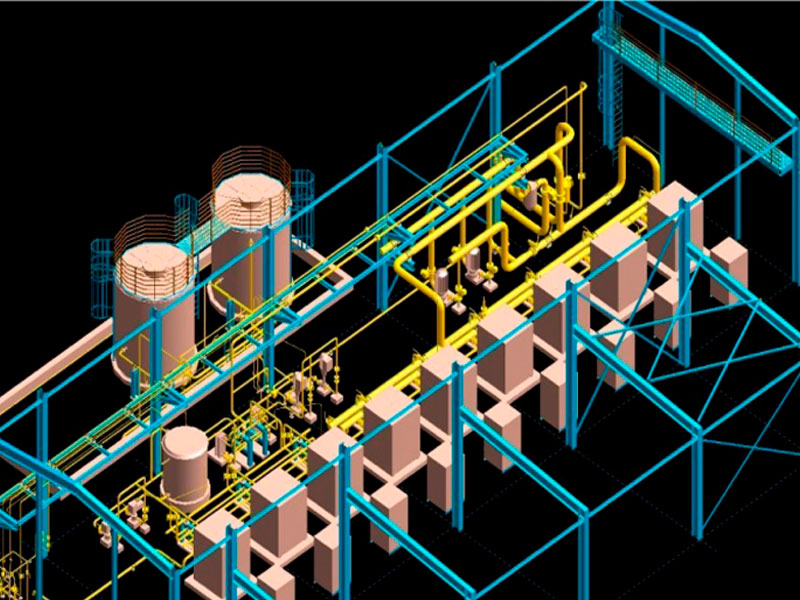

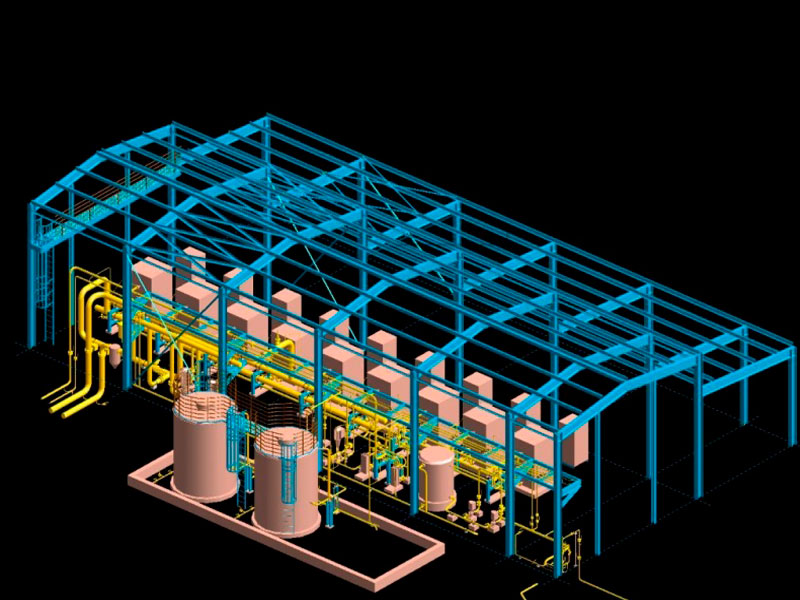

Samarkand city boiler house

Samarkand city boiler house

Projects implemented to date by the specialists of Teploelektroproekt JSC at AVEVA Plant:

Kurgan CHPP-2, "Construction of 2 steam-gas plants with a total capacity of 220 MW" (Russian Federation, Kurgan);

"Model project to improve energy efficiency through highly efficient gas turbine cogeneration technology at the Tashkent CHP", a joint project of NEDO (Japan) and SJSC Uzbekenergo RUz (Uzbekistan, Tashkent);

"Expansion of the open boiler group of the CHPP with the installation of an additional 4 boilers"

CHPP of OJSC "Almalyk Mining and Metallurgical Plant" Reconstruction of CHP. Installation of a boiler type E-75-3.9-440GM st. N5 (Uzbekistan, Almalyk);

Construction of an electric boiler house in Samarkand (Uzbekistan)

Currently, the institute is transitioning from AVEVA Plant 12.0 to AVEVA Plant 12.1, which allows using additional internal program tools, namely, an improved reporting mechanism, an increase in system performance and speed, an updated interface, more perfect integration between applications.

The new version of the AVEVA Plant 12.1 system uses an improved graphical user interface that provides the necessary integration between different applications. The system has become more functional, as users have the opportunity to create report templates using the Report Designer application, supplement reports with images and tables. These diagrams are much easier to understand and use in presentations. In addition, users have access to a standard equipment catalog, and can also repeatedly use existing models of complex equipment, either in full or in part. Thus, labor costs are significantly reduced.

In the updated version, the AVEVA Engineering application has appeared, which allows you to develop a base of engineering characteristics for the designed object (pipeline, equipment element, etc.). Moreover, work on an object can be carried out by several specialists from different departments at once, when each of them edits the characteristics for which one or another engineering discipline is responsible. This approach allows you to work on a single element.

Capabilities of the 3D design team

Today, with the help of the 3D design software package PDMS "AVEVA", specialists of Teploelektroproekt JSC have the opportunity carry out the following types of work:

![]() Receive ready-made assembly drawings, isometric drawings of pipelines, specifications of pipelines and equipment

Receive ready-made assembly drawings, isometric drawings of pipelines, specifications of pipelines and equipment

![]() Issue the finished design and estimate documentation at various stages of project development. This allows construction work to begin before the project is complete.

Issue the finished design and estimate documentation at various stages of project development. This allows construction work to begin before the project is complete.

![]() Respond promptly to assembly inconsistencies. The created three-dimensional model of the object allows you to quickly make various changes to the project and, as a result, obtain modified working documentation.

Respond promptly to assembly inconsistencies. The created three-dimensional model of the object allows you to quickly make various changes to the project and, as a result, obtain modified working documentation.

![]() Accompany renovations. The image of the reconstructed objects in a three-dimensional model allows you to develop a reconstruction plan in more detail and efficiently

Accompany renovations. The image of the reconstructed objects in a three-dimensional model allows you to develop a reconstruction plan in more detail and efficiently

![]() Convert 2D drawings to 3D models. A three-dimensional model allows you to more efficiently arrange equipment and pipelines, which will allow you to issue more detailed custom specifications, avoid spatial collisions during installation, and take into account places for personnel passage and equipment maintenance.

Convert 2D drawings to 3D models. A three-dimensional model allows you to more efficiently arrange equipment and pipelines, which will allow you to issue more detailed custom specifications, avoid spatial collisions during installation, and take into account places for personnel passage and equipment maintenance.

![]() Perform catalogs and customizations for customers who have the program but do not have trained personnel. The ability to administer a group of three-dimensional design and cataloging of equipment, pipeline parts and a range of rolled metal products

Perform catalogs and customizations for customers who have the program but do not have trained personnel. The ability to administer a group of three-dimensional design and cataloging of equipment, pipeline parts and a range of rolled metal products

![]() Prepare presentations. The Review module allows you to perform a detailed display of the submitted project using various visual effects.

Prepare presentations. The Review module allows you to perform a detailed display of the submitted project using various visual effects.

100015, Republic of Uzbekistan, Tashkent, Mirabad district, st. Shakhrisabzskaya 22

100015, Republic of Uzbekistan, Tashkent, Mirabad district, st. Shakhrisabzskaya 22 (+99878) 140-67-01

(+99878) 140-67-01 Fax: (+99878) 140-67-28

Fax: (+99878) 140-67-28  E-mail:tep@sks.uz

E-mail:tep@sks.uz